Stick Welding - How to Arc Weld Techniques

How To Stick Weld For Greater Results with Confidence

Hot tips and tricks to help improve your welding skill and confidence with Insider secret techniques!

Professional welders create perfect welds by recognizing imperfections, grinding them out and re-welding.

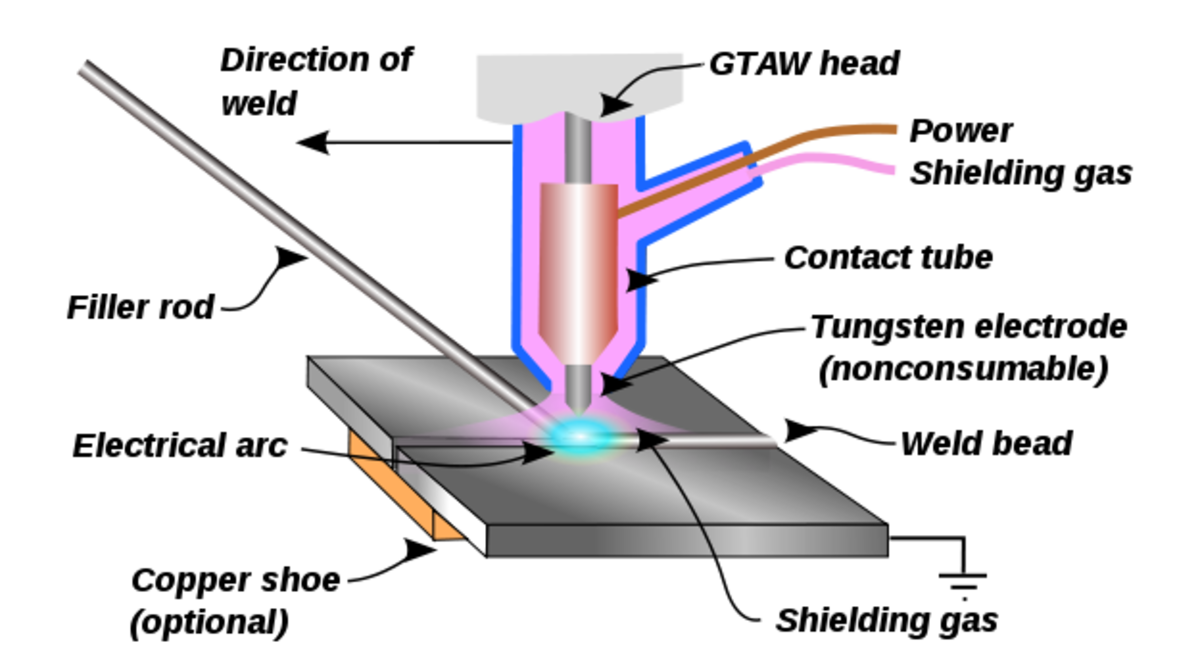

If you're just learning the "stick" welding, technically this process is called Shielded Metal Arc Welding...

Keep reading the step-by-step, hot-off-the-press tips, it can make your welding experience enjoyable and improve your welding technique. Period!

OK! So you want to be a better welder...quick and easy.

Firstly a few words of practical advice before diving in, stick welding isn't that easy because there's a lot to know even before you actually start welding.

The name of the game here is experience, when you're welding you need a good view of the weld puddle.

The best way is to keep your head slightly off to one side out of the way from the smoke so you can easily see exactly what you're doing...

More importantly see and/or monitor the molten metal puddle.

Otherwise, you're guessing as to whether you're welding in the joint, or to the bench, lol (don't laugh, I've welded parts to the bench before, not funny:)

So keep the arc on the leading edge of the puddle, using the right amount of heat (you can actually see a puddle with too much heat roll out of the joint).

The five simple basics to understand and master are:

1: The current setting

2: The length of arc

3: The angle of electrode

4: The approach or manipulation of electrode

5: The speed of travel...

The trick is to learn from your mistakes and that means...go for it!

Now let's start with bringing all these tips together because there's a lot to think about, but it becomes second nature with practice.

Look, I'll be honest in saying your first attempt to stick weld maybe scary as heck, because everyone sticks the rod to the workpiece when learning how to weld...

My advice is to hang in there, don't get discouraged, you're not on your own!

OK. On the side of the electrode box you'll find a table of amp ranges which usually indicates operating ranges, it's important to set the amps on the diameter and type of electrode you've selected...

Most modern welding machines have a fixed chart with guide lines for correct amperage settings including a variety of electrodes and material thicknesses.

The correct current or amperage is critical to the process, for example, a 1/8 inch 6010 rod flows or runs well set at current range from 75 to 125 amps, while a 5/32 inch 7018 rod welds at currents up to 220 amps.

Select an amperage based on the material's thickness, welding position (about 15 percent less heat for overhead work compared to a flat weld) and observation of the finished weld.

The correct arc length varies with each electrode type, material and the application.

As a guide for arc length, this should be the inner (core) metal portion and not exceed the diameter of the (core) of the electrode.

If you're holding the electrode too close to the material this decreases welding voltage, creating an erratic arc that could extinguish itself or cause the rod to freeze, as well as produces a weld bead with a high crown.

Excessively long arcs (too much voltage) produces spatter, low deposition rates, undercuts and maybe porosity (and lack of penetration).

Many beginners weld with too long of an arc, so they produce rough beads with lots of spatter.

A little practice will show you that a tight, controlled arc length improves bead appearance, creates a narrower bead and minimizes spatter.

Stick welding in the flat, horizontal and overhead position uses a "drag" or "backhand" welding technique. Hold the rod perpendicular to the joint and tilt the top of the electrode in the direction of travel approximately 5 to 15 degrees.

For welding vertical up, use a "push" or "forehand" technique and tilt the top of the rod 15 degrees away from the direction of travel.

Each welder's approach is different, manipulating or weaving the electrode in a unique style.

The idea is to develop your own style by observing others, practicing and then creating a method that produces good results for you.

To create a wider bead on thicker material, manipulate the electrode from side to side creating a continuous series of partially overlapping circles, or in a "Z," semi-circle or stutter-step pattern.

Limit side-to-side motion to 2-1/2 times the diameter of the electrode core.

It's easier to cover a wider area by making multiple passes or "stringer beads."

When you're welding vertically up, just focus on welding the sides of the joint rather than the middle...(the middle will take care of itself.)

Pause slightly at the side to allow the far side of the bead to cool, the weld puddle to catch up, and to ensure solid "tie-in" to the sidewall.

For example, if your weld looks like fish scales, you're moving forward too quickly and you're not holding long enough on the sides.

The proper travel speed produces a weld bead with the desired contour (or "crown"), width and appearance is uniform and smooth.

Adjust travel speed so that the arc stays within the leading one-third of the weld pool.

Slow travel speeds produce a wide, convex bead with shallow penetration.

Excessive travel speeds also decrease penetration, create a narrower and/or highly crowned bead, and possibly undercuts...

How to carefully prepare joints and fittings for E6010 electrode on rootpass open root pipe weld using 3 step technique:

1. Pipe joints need to fit-up, that means neat and clean for welding if you want good results. Make sure weld edges are clean of loose materials: grind surfaces of scale, slag, rust, paint, oil, etc, for correct vertical and horizontal alignment.

2. Make sure bevels are cut accurately. Fillet welds are used for welding slip-on orthreaded flanges to pipe. Make sure welding machine is set to correct amp settings.

3. Use correct welding technique, butt joints are used between pipes and welded fittings. Inpreparing a butt joint, simply place two pieces of pipe end to end, align and weld.

Open root welds on pipe or plate require proper beveling to reduce both the amount of fillermetal required which, in turn, reduces time and expense. What does proper alignment or fit-up means if the joint match is poor?

The fit-up is the horizontal and vertical alignment using a range between 1/16" to 1/8 of an inch gap between two pipes. Ideally you want the bevel and gap to be consistent all the way around the pipe.

Correct setting of the welding machine requires following the electrodes manufacture's recommended amperage range for electrode. In this example for a root pass with E6010 you can start at the low end of the recommended amperage setting.

Now, run a short bead on the root so you can tweak amperage setting until it is just right. You can practice on scrap metal to set welder just hot enough to barely weld without sticking.

Any root openings or joint angles must be consistent for the entire length of a joint. The welding technique for E6010 electrode on an open root pipe weld is always a whipping motion.

The only factor that really changes with this technique is whipping motion from back and forth as much as one inch as little just as a slight shake of electrode to get good root penetration.

Once you strike the arc, open up a keyhole and keep the arc inside which is important if a good weld is to be made and this all comes back to the fit-up of the joint selected for any job affects the quality, strength and appearance of finished weld.